Solutions

Safeguard against unplanned downtime

Reliability, a key challenge for manufacturing operations.

It is estimated that industrial manufacturers lose a staggering €40 Billion every year due to unplanned downtime. Maintenance expenses make up anywhere between 20-40% of total production costs where only 20% of machine failures are age-related.

Using VersaSense solutions for machine health monitoring, you can monitor and predict unforeseen machine failures in the most harsh industrial environments.

implement asset monitoring in minutes

Install. Diagnose. Report.

Our award-winning IoT technology implements the most advanced wireless for harsh industrial environments. With VersaSense you can quickly enable predictive maintenance on your industrial asset base.

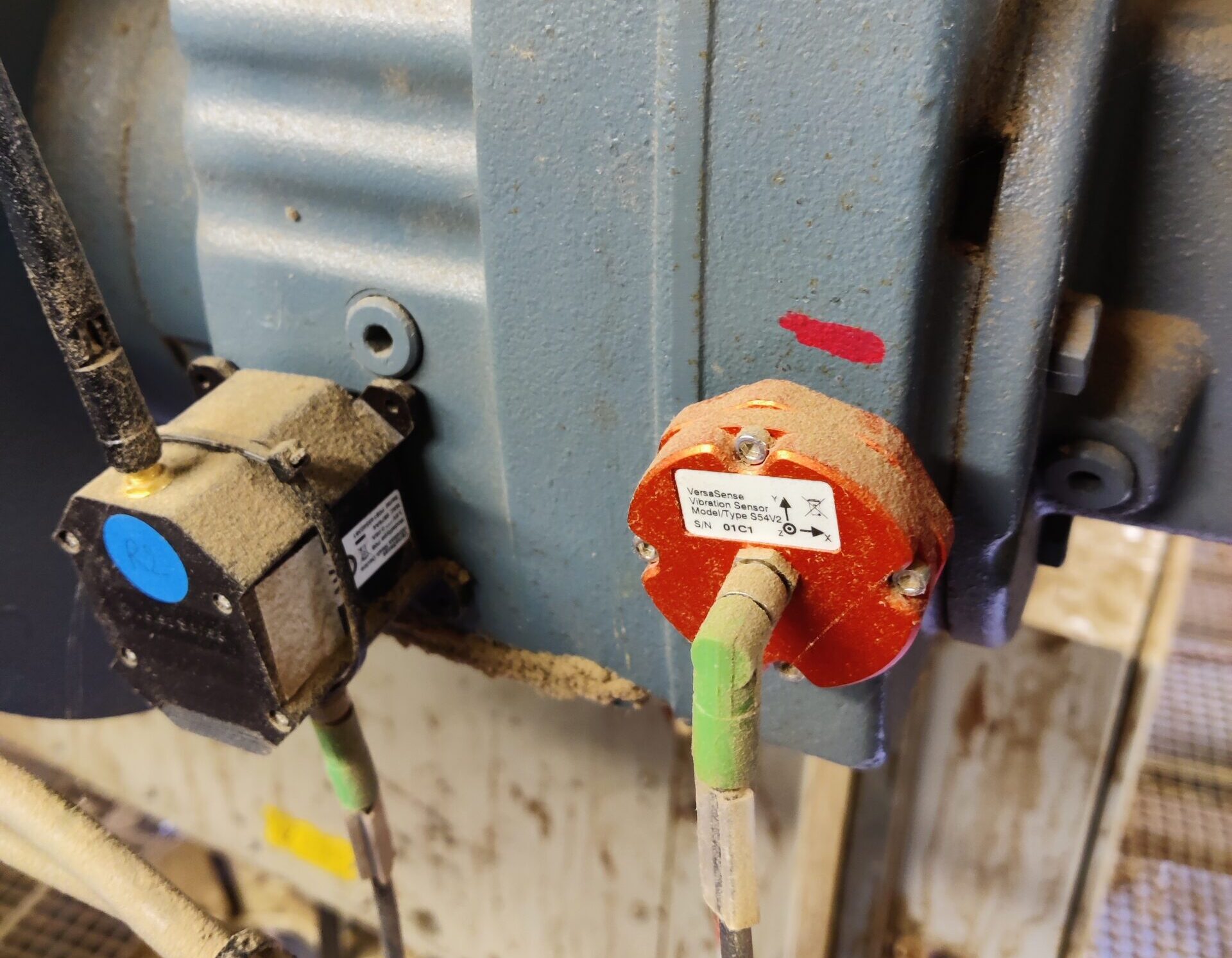

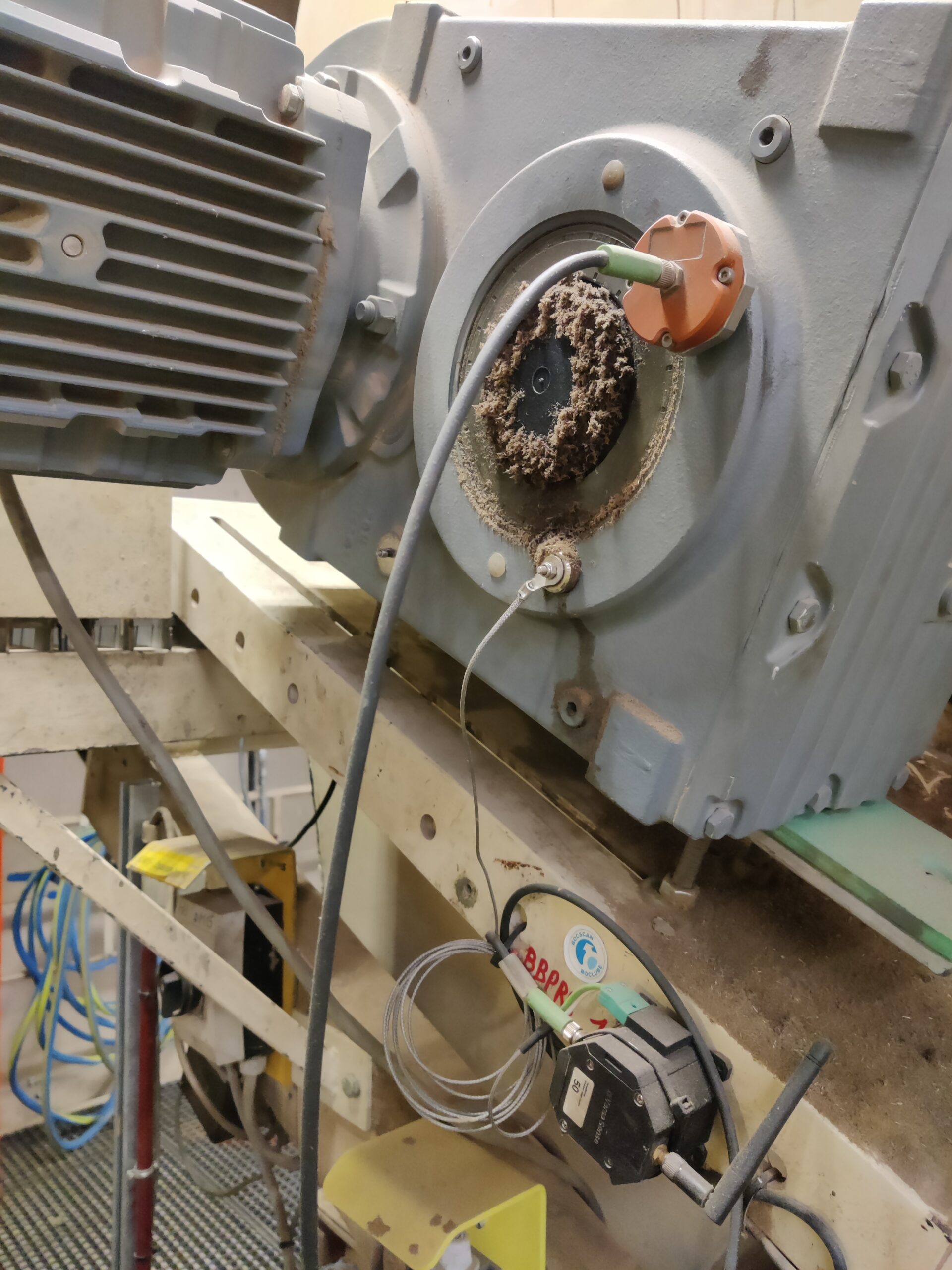

Install sensors

Simply mount intelligent plug and play sensors such as vibration or temperature on your industrial assets. The sensors automatically form a robust self-organising wireless network, collect sensor data, and perform feature extraction on the captured sensor data.

Monitor, Predict, Alert

Indicate a training period and the VersaSense analytics platform will automatically process all captured data to establish trends and anomalies, fire off alerts, and generate relevant reports.

Diagnose & Improve

Use available detailed data to troubleshoot issues and plan maintenance tasks. Link generated insights with maintenance activities and prevented faults. Refine thresholds and analytics recommendations.

Customer Success Stories

Discover how Unilin Panels uses VersaSense to tackle unplanned downtime across their chipboard production plants.

Machine Health

Failure Prediction

Condition Alerting

Everything required to run predictive maintenance at scale

Predict & Prevent

AI-driven Machine Health on the Cloud

Imagine empowering your maintenance teams with the future of reliability. VersaSense goes beyond basic monitoring, providing long-term trend analysis through periodic health reports. These reports deliver a crystal-clear overview of your entire machine pool, highlighting potential issues and predicting failure risks.

The result? Proactive, data-driven maintenance. Instead of scrambling to fix unexpected breakdowns, your team can schedule interventions well in advance, minimizing downtime and maximizing productivity.

But that’s not all. VersaSense is a continuous learning platform. As your team records their activities in the detailed equipment log, the system integrates their expertise into its AI models. This continuous feedback loop strengthens the platform’s prediction capabilities, ensuring even more accurate insights over time.

VersaSense empowers you to:

- Predict machine problems before they happen.

- Reduce downtime and maintenance costs.

- Extend machine lifespan and ROI.

- Boost team efficiency with proactive maintenance.

- Continuously improve the platform’s accuracy through expert feedback.

Easy setup

Get Insights Faster with Automatic Learning and Data Quality Management

The VersaSense AI-powered software platform for machine insights goes beyond just collecting data. We ensure your data is high-quality and ready to generate actionable insights, saving you time and effort.

Automatic Learning:

- Schedule training periods easily after maintenance when machines are healthy.

- Automatically (re)train the system whenever needed, no manual intervention required.

- Learn what “normal” operating conditions look like for accurate anomaly detection.

Seamless Data Quality Management:

- Continuously monitor data streams for gaps, sensor issues, downtime, and outdated information.

- Automatic data quality checks and reports highlight potential problems.

- Immediate alerts for critical issues like missing or suspicious data during training.

Effortless Integration and Scalability:

- Leverage all VersaSense Platform features, including:

- Infrastructure configuration management and monitoring

- Support for multiple sites and users

- Seamless integrations with leading OT historians, such as AVEVA PI System (formerly OSISoft PI), and cloud-based platforms like Azure or SAP.

Ready to transform your maintenance strategy? Contact VersaSense today and see how AI can predict the future, prevent problems, and empower your team to succeed.